| 1. |

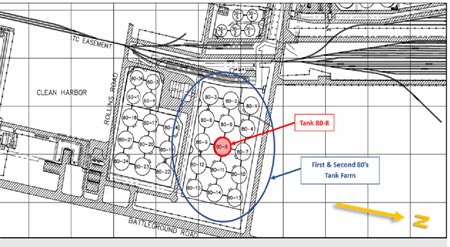

The incident occurred in what was commonly referred to as the First & Second 80’s tank farm at the ITC Deer Park terminal (Figure3). The first & Second 80’s tank farm consisted of fifteen (15) 80,000-barrel (3,360,000- gallon) capacity above ground atmospheric storage tanks situated within a common containment area that measured approximately 732 feet in length by 449 feet in width. The storage tanks measured 110 feet in diameter and 48 feet in height and were arranged in a 3 x 5 grid pattern, oriented in the east-west direction lengthwise.

|

|

|

True |

|

|

False |

| 2. |

The above ground atmospheric storage tank involved in the initial fire, Tank 80-8, was positioned in the center of the First & Second 80’s tank farm (Figure 3 and 4).

|

|

|

the center of the First & Second 80’s tank farm |

|

|

the corner of the First & Second 80’s tank farm |

| 3. |

Figure 11 showstank 80-8 on fire when the fire first started. |

|

|

True |

|

|

False |

| 4. |

No alarms to alert personnel about the_________________________________. Consequently, the butane-enriched naphtha product continued to release from the failed pump for approximately 30 minutes, completely undetected, before its flammable vapors eventually ignited. (Section 4.2) |

|

|

initial release of butane-enriched naphtha product around theTank 80-8 piping manifold |

|

|

Fire |

| 5. |

Tank 80-8 was equipped with a fixed foam system that injected foam into the tank to cover the flammable liquid, to suppress the flammable vapors and cut off oxygen supply necessary to support combustion. The fixed foam system on Tank 80-8 was a manually activated system, with supply coming from fire trucks. The hose connection point was located at the Second 80 spipingmani fold by Tanks 80-9 and 80-12, which was inundated with fire. This made the area inaccessible to responders. |

|

|

A manually activated system |

|

|

A remotely controlled activating service |

| 6. |

Tank 80-8 was not equipped with a remotely operated emergency isolation valve (ROEIV) therefore, the Unified Command discussed trying to manually isolate the main valves on the tank. However, because flames engulfed the entire Tank 80-8 piping manifold, so the area could not be safely accessed, allowing the continued release of butane-enriched naphtha product from Tank 80-8. At approximately 3:00 p.m., the Unified Command sent a team inside the containment area to close the main valves on some of the other tanks in the tank farm.

While the team was inside the tank farm, flammable xylene vapors at the roofline of a second storage tank (Tank 80-5) ignited. Concerned for the team’s safety, the Unified Command directed the responders to exit the tankfarm before they could successfully close any valves. The fire eventually compromised the Tank 80-5 piping manifold, causing xylene to release into the containment area.

|

|

|

True |

|

|

False |

| 7. |

Responders continued to fight the fire in defensive mode throughout the evening, applying water and foam to prevent the fire from spreading further. However, the large amount of water in the tank farm containment area and gaps in the foam blanket allowed the fire to spread. Both naphtha and xylene are lighter than water, therefore, the released flammable products floated on top of the water in the containment area, ignited, and caused several small fires to burn on the water surface where gaps in the foam existed. |

|

|

True |

|

|

False |

| 8. |

According Fig. 14, the fire was fully extinguished approximately ____________ after it started. |

|

|

In 2 hrs. |

|

|

In 8 hrs. |

|

|

Over 24 hrs. |

| 9. |

Pump Mechanical Integrity. The CSB concluded thatITC did not have a formal mechanical integrity procedure in place that defined requirements for maintaining the mechanical integrity of Tank 80-8 and its associated equipment, including the Tank 80-8 circulation pump. A formal mechanical integrity program for pumps in highly hazardous chemical service _____________ prevented this incident by providing ITC with additional opportunities to identify pump issues prior to the incident. The mechanical seal on the pump failed on March 17, 2019, allowing butane-enriched naphtha product to release from the pump whileit continued to operate. (Section 4.1) |

|

|

Could have |

|

|

Could not have |

| 10. |

Flammable Gas Detection Systems. Tank 80-8 was not equipped with a flammable gas detection system to warn personnel of a hazardous atmosphere resulting from loss of containment from the tank or its associated equipment ________________________________________________________________________; however, ITC did not implement this recommendation, and did not document why it was not implemented. In the absence of a flammable gas detection system, there were |

|

|

In 2014, a hazard review team recommended the addition of flammable gas detection systems near Tank 80-8; |

|

|

A gas detection system was never considered or recommended near Tank 80-8 |

| 11. |

Remotely Operated Emergency Isolation Valves. Tank 80-8 and the other above ground storage tanks located in the First & Second 80’s tank farm were not equipped with remotely operated emergency isolation valves (ROEIVs) designed to mitigate process releases remotely from a safe location. If they were equipped with ROEIVs the fire ____________ distinguished a lot sooner.

|

|

|

Could have been |

|

|

Would not make any difference |

| 12. |

Tank Farm Design. Although the First & Second 80’s tank farm was designed largely in accordance with applicable National Fire Protection Association (NFPA) 30 requirements, elements of the tank farm design, including tank spacing, subdivisions, engineering controls for pumps located inside the containment area, and drainage systems, made it difficult for emergency responders to slow or prevent the spread of the initial fire and allowed the fire to spread to other tanks within the tank farm. While NFPA 30 defines minimum requirements for tank farm design, additional industry guidance documents provide more robust tank farm design recommendations. While ITC ____________ required to implement additional industry guidance recommendations, many of which were developed after construction of the First & Second 80’s tank farm, implementation of such recommendations could have prevented the escalation of this incident.

|

|

|

Was not |

|

|

was |

| 13. |

The CSB determined that the cause of the incident was the release of flammable butane-enriched naphtha vapor from the failed Tank 80-8 circulation pump, which accumulated in the area and ignited, resulting in a fire. Contributing to the severity of the incident were the absence of a flammable gas detection system to alert the operators to the flammable mixture before it ignited approximately 30 minutes after the release began, and the absence of remotely operated emergency isolation valves (ROEIVs) to safely secure the flammable liquids in Tank 80-8 and the surrounding tanks in the First & Second 80’s tank farm. |

|

|

True |

|

|

False |

| 14. |

Elements of the tank farm design, including tank spacing, subdivisions, engineering controls for pumps located inside the containment area, and drainage systems also contributed to the severity of the incident by allowing the fire to spread to other tanks within the tankfarm. The resulting accumulation of hydrocarbon and petrochemical products, firefighting foam, and contaminated water in the secondary containment area ultimately contributed to a breach of the containment wall and a release of materials to the local waterways. |

|

|

True |

|

|

False |

| 15. |

Finally, the CSB determined that because of the atmospheric storage tank exemption contained in the OSHA PSM standard and the flammability exemption contained in the EPARMP rule, _____________ to develop and implement a formal PSM program for Tank 80-8 and its associated equipment that could have provided a process to identify and control the specific hazards that resulted in this incident, which also contributed to this incident. |

|

|

ITC was not required |

|

|

ITC was required |

|