| 1. |

Structural designs are based on flexural strengths that the concrete is expected to obtain at 28 days for road pavements and 90 days for airfield pavements. |

|

|

True |

|

|

False |

| 2. |

The 14-day field control strength (ffc) will be determined as follows:

Where:

fcorr = 14-day flexural strength that is correlated (28 or 90-day strength)

SD=?

What does SD mean? |

|

|

Standard deviation of flexural strength results |

|

|

Simple derivation results |

|

|

Standard design test results |

|

|

None of the above |

| 3. |

The specified air content will be 10 ± 1½ percent for concrete pavements located in regions where resistance to freezing and thawing is a prime consideration. |

|

|

True

|

|

|

False

|

| 4. |

Either the contractor or the contracting officer may be responsible for cement-mixture proportioning. When the contractor is responsible for mixture proportioning, no separate payment will be made for cement. When the contracting officer is responsible for mixture proportioning, no limits for the quantity of cement content will be included in the contract specifications; the quantity of cement used per cubic yard of concrete will be determined by the contracting officer, and cement will be paid for under a separate bid item. |

|

|

True

|

|

|

False

|

| 5. |

Five Portland cements designated as Type I through V are marketed today. In these which type of cement is commonly used, unless otherwise specified? |

|

|

Type I

|

|

|

Type II

|

|

|

Type III

|

|

|

Type IV & V

|

| 6. |

High alumina cement, also known as aluminous or calcium aluminate cement, gains most of its strength in one day, is resistant to chemical attack, and is a refractory material. |

|

|

True

|

|

|

False

|

| 7. |

Existing concrete may be taken up, crushed to suitable gradation, and re-used as concrete aggregate. (But it must meet all the requirements for gradation and quality that conventional aggregates must meet.) |

|

|

True

|

|

|

False

|

| 8. |

The maximum size of the coarse aggregate used in pavement concrete should not exceed one-fourth of the pavement thickness. In no case will the coarse aggregate exceed a 2-inch maximum size. |

|

|

True

|

|

|

False

|

| 9. |

Admixtures may be used to improve workability, control initial set, reduce heat generation, accelerate strength gain, increase strength, and improve durability. |

|

|

True

|

|

|

False

|

| 10. |

Subgrade is the natural soil or fill, upon which the base and concrete pavement are placed. |

|

|

True

|

|

|

False

|

| 11. |

Plastic shrinkage (craze) cracking is caused by a combination of (1) high ambient air temperature, (2) high concrete temperature, (3) low relative humidity, and (4) wind velocity. |

|

|

True

|

|

|

False

|

| 12. |

Joints are constructed in concrete pavement to permit contraction and expansion of a pavement without irregular cracking and as a construction expedient to separate the paved area into strips necessary for handling and placing of concrete. |

|

|

True

|

|

|

False

|

| 13. |

Sawed contraction joints must be cut deeper to insure opening of all joints. The saw cut must penetrate one-third to one-half of the slab thickness. |

|

|

True

|

|

|

False

|

| 14. |

Roller-compacted concrete pavement employs a concrete paving technology that involves laydown and compaction of a zero-slump concrete mixture using equipment similar to that used in placement and compaction of asphaltic concrete pavement. |

|

|

True

|

|

|

False

|

| 15. |

One of the most important factors in determining the quality and economy of concrete is the selection of a suitable aggregate source. |

|

|

True

|

|

|

False

|

| 16. |

Because of the low water content used in an RCCP (roller-compacted concrete pavement) mixture, a combination of moist curing and membrane curing is recommended to prevent drying and scaling of the RCCP surface. |

|

|

True

|

|

|

False

|

| 17. |

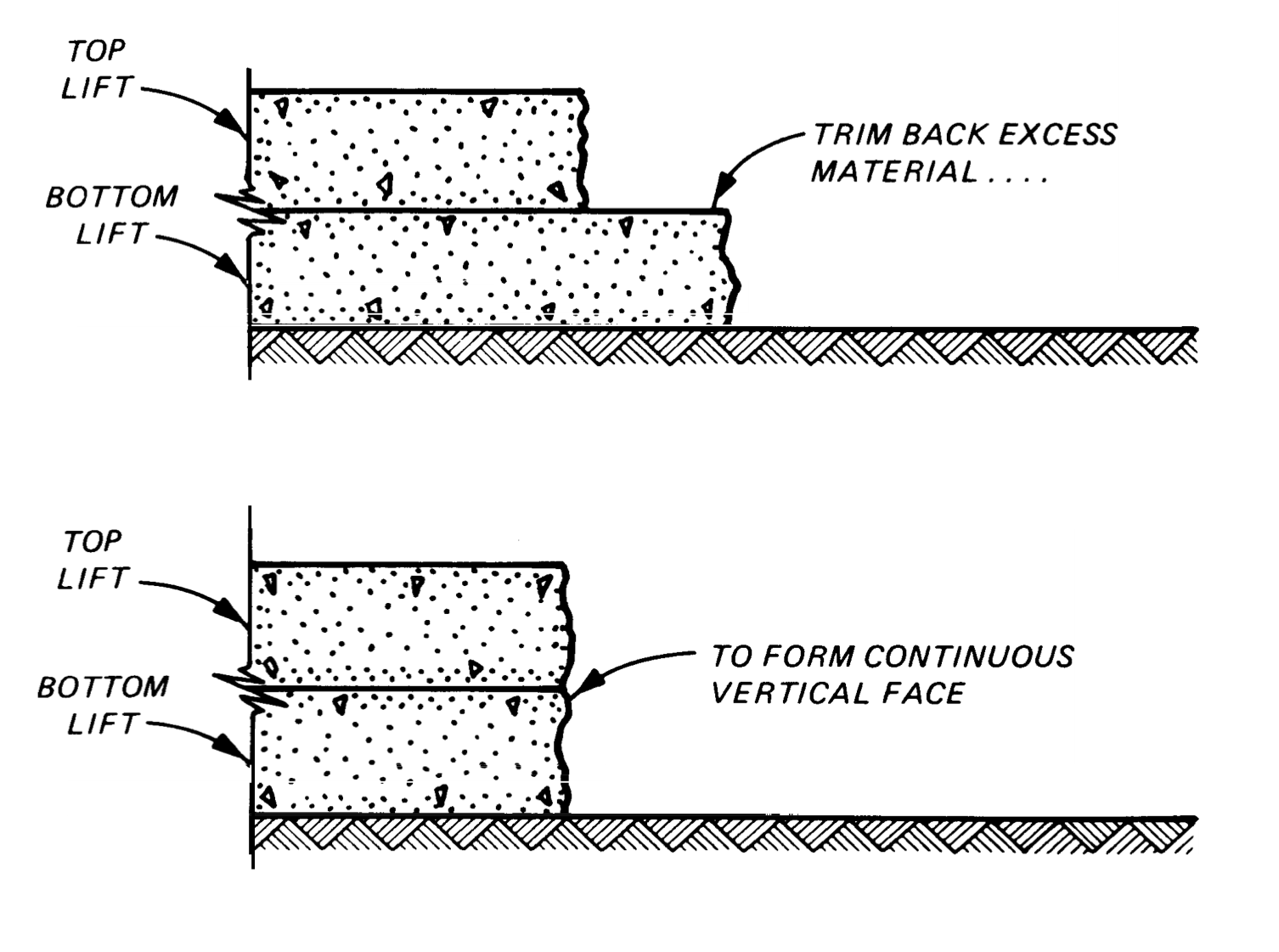

Figure 1A

What does figure 1A illustrate? |

|

|

Compaction of interior paving lanes

|

|

|

Construction of a cold joint

|

|

|

Two-lift cold joint

|

|

|

None of the above

|

| 18. |

Quality control and quality assurance consist of testing of materials going into the concrete; checking the plant calibration regularly; measuring the in-place density of the RCCP (roller-compacted concrete pavement) using a nuclear density gage; checking the smoothness of the finished RCCP with a straightedge; taking core samples from the RCCP for measurement of density, strength, and thickness; and, if desired, fabricating RCC (roller-compacted concrete) cylinders and beams. |

|

|

True

|

|

|

False

|

| 19. |

Inspections are vital in the quality control operations. At least one inspector should be stationed at the mixing plant and at the jobsite to insure that a quality pavement is being built. |

|

|

True

|

|

|

False

|

| 20. |

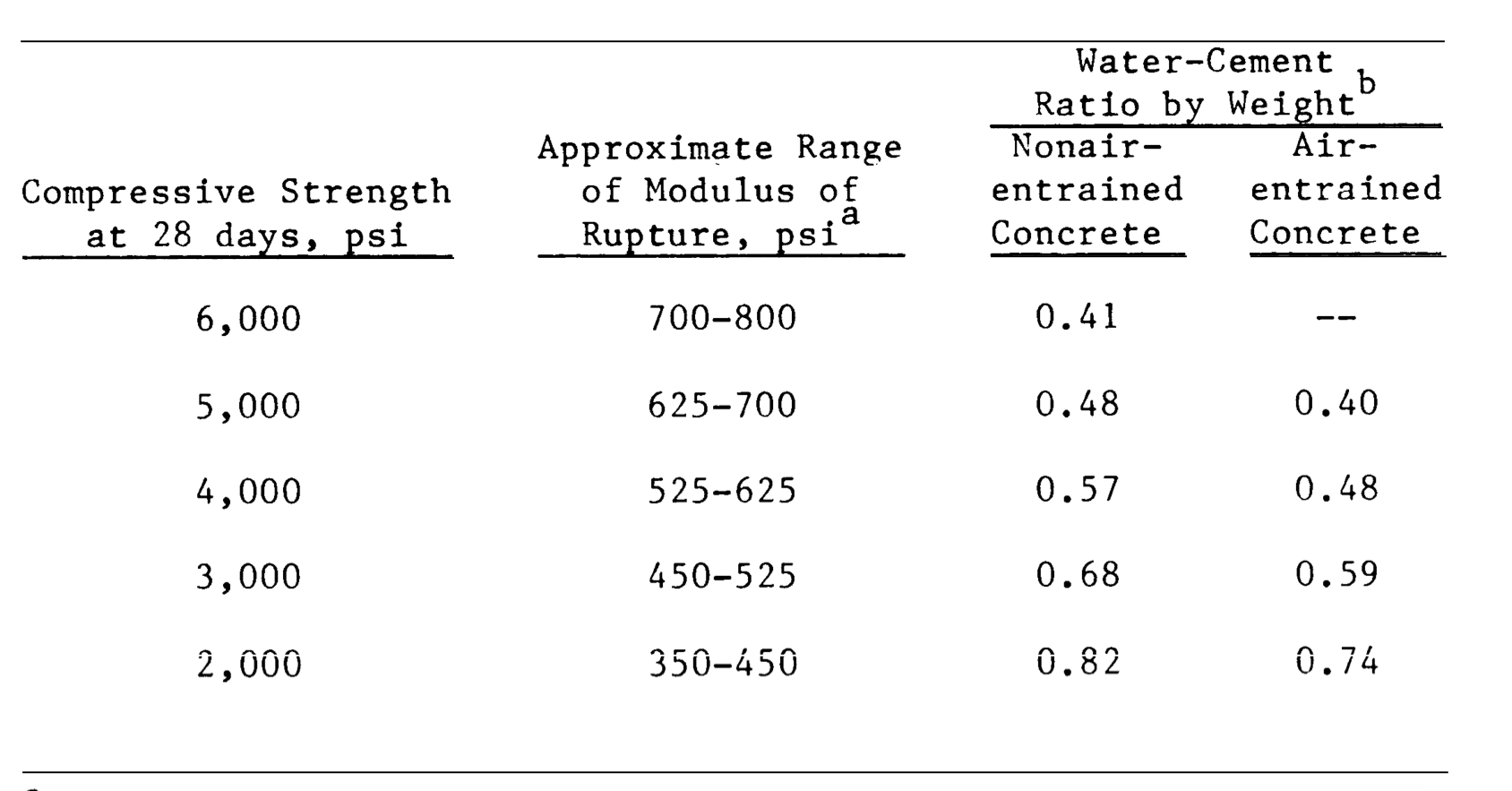

Table 1.0

What does Table 1.0 say about? |

|

|

Grading of fine aggregate

|

|

|

Approximate relation between water-cement ratio and strengths of concrete

|

|

|

Deleterious materials in coarse aggregates for other pavements

|

|

|

None of the above

|

|